-

Mobile Version

Scan with Mobile

- Member Center

421

421

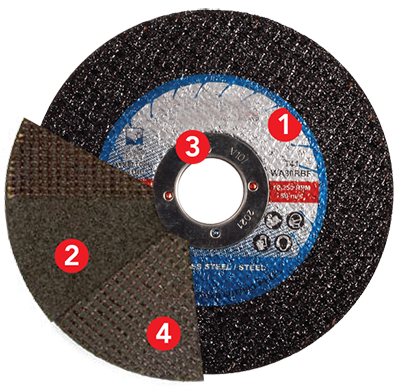

Label & Cover Sheet (1)

The label includes all of the important information on the product, manufacturer and information on the proper usage of the grinding tool.

Mixture (2)

The Grit: Today all grit types are only produced synthetically. Only grit produced synthetically can ensure continuously high wear and disc quality.

Resins and fillers: Additional, important components for cutting and grinding discs are resins, (in liquid and dry form), and fillers. These components are key to determining the disc properties, such as stability, stock removal rate, shear strength and can be adjusted to meet the needs of the specific application.

Metal Ring (3)

Provides information on the expiry date of the disc.’

Glass Fibre Disc (4)

Glass fibre is a reinforcing layer to ensure stability and increases the safety of the cut-off wheel.

The number and strength of the glass fibre layers are dependent upon disc type and application. The higher the potential lateral load on a cut-off disc (it is greater during free cutting than during stationary cutting). The more glass fibre that the cutting disc must contain or the contained glass fibre must be more stable. The particularly thin material is used for thin cutting discs (0.8 mm to 1.0 mm), to despite the thin discs, ensure that a large grit ratio is achieved between the layers. Grinding wheels are constructed with at least 2 glass fibre layers.